From Planning to Perfection: Our Production Timeline

Your projects journey.

Social Responsibility in Control Cabinet Construction

SchubS GmbH organizes material procurement and pre-assembly for control cabinet construction in close cooperation with social workshops in Hamelin and Holzminden that employ people with disabilities.

Komax Zeta 633: Efficiency in Control Cabinet Construction

To optimize production time and costs, we rely on the fully automated Komax Zeta 633 System for internal cable production. This boosts the efficiency of our control cabinet construction.

Precision in Control Cabinet Construction

For precise control cabinet construction, we use an EPLAN-controlled Steinhauer milling and drilling center. The system automatically creates cutouts in mounting plates, which further perfects our automation technology.

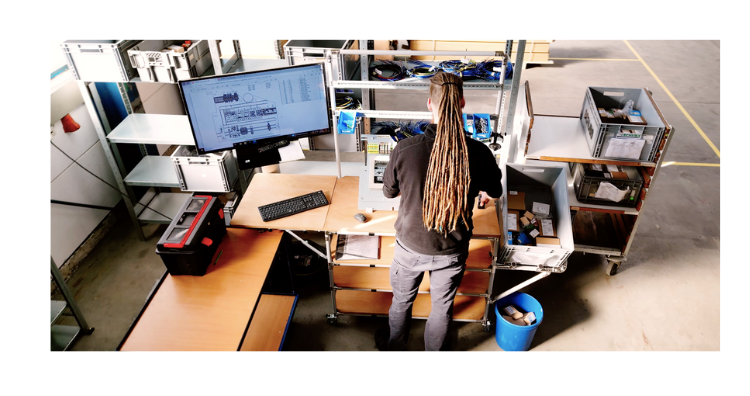

Our DAKoTA

Thanks to our DAKoTA software, the outfitting of mounting plates for control cabinet construction is nearly paperless. This increases efficiency and promotes the digitalization of our production.

Moonshiner: Augmented Reality in Control Cabinet Construction

Our visual assistance system Moonshiner accelerates assembly by projecting layout diagrams directly onto the mounting plate using Augmented Reality. This makes the entire control cabinet manufacturing process paperless.

Final Assembly with Precision in Control Cabinet Construction

Following pre-fabrication, the final assembly of components takes place inside the control cabinet. Parts are secured and all screws are tightened to the exact specified torque to ensure maximum precision and quality.

Quality Assurance in Control Cabinet Construction

The final step for every control cabinet is a thorough quality assurance check. A careful test and final check with the design voltage guarantees maximum precision. Full documentation of all values ensures final acceptance.

Learn more about Schubs and how we've been leading switch control experts since the 90s.

Learn more about Schubs and how we've been leading switch control experts since the 90s. Learn how our responsible engineering & sustainable practices create long-term value for our customers and our planet.

Learn how our responsible engineering & sustainable practices create long-term value for our customers and our planet. UL-certified for peace of mind. We build control cabinets that are a mark of quality, precision, and global safety standards.

UL-certified for peace of mind. We build control cabinets that are a mark of quality, precision, and global safety standards. Take a look at some of the services offered by Schubs and see how we can help you!

Take a look at some of the services offered by Schubs and see how we can help you! Follow our process from planning to the finished product.

Follow our process from planning to the finished product. Learn how Schubs continuously adapts to digitalisation for our manufacturing.

Learn how Schubs continuously adapts to digitalisation for our manufacturing.