Digital Innovations in Control Cabinet Construction

Schubs GmbH uses RoboSchalt (wiring automation), DAKoTA (efficient data processing), and Moonshiner (Augmented Reality for assembly) to advance production and automation technology.

-1.png?width=381&height=416&name=Untitled%20design%20(7)-1.png)

Roboschalt

RoboSchalt: Revolutionizing Control Cabinet Construction

Schubs GmbH and the Ruhr-Universität Bochum have launched the funded research project RoboSchalt. The goal is automated wiring of control cabinets using a robot.

This cyber-physical system (CPS) solves the problem of single-piece production and significantly improves efficiency, safety, and cost. An innovation in control cabinet construction with great potential for automation technology and Industry 4.0.

-1.png?width=381&height=416&name=Untitled%20design%20(8)-1.png)

DAKoTA

DAKoTA: Digitalization in Control Cabinet Construction

DAKoTA is our in-house data processing (Datenverarbeitung) solution. It optimizes production for small-batch and large-scale manufacturing.

This paperless system streamlines workflows and is accessible for all employees.

A modular tool for industries like electrical engineering (Elektrotechnik), it advances automation technology (Automatisierungstechnik) and is a perfect fit for Industry 4.0 (Industrie 4.0).

-1.png?width=381&height=416&name=Untitled%20design%20(9)-1.png)

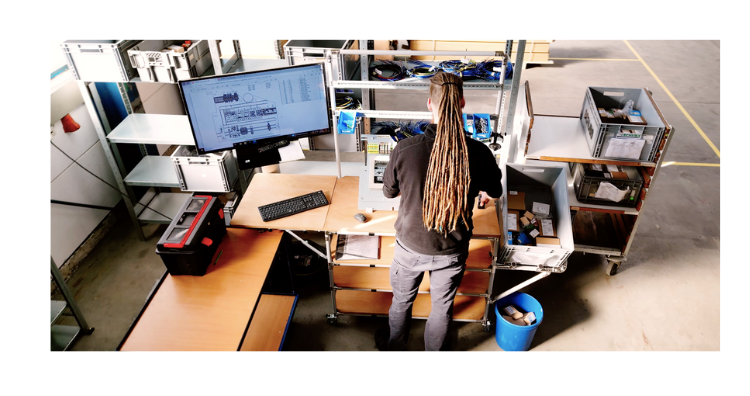

Moonshiner

Moonshiner: Visual Assistance Systems for Control Cabinet Construction

Through our visual assistance system Moonshiner, which uses Augmented Reality, we are digitalizing the production of control cabinets. Employees save time and reduce errors by viewing digital blueprints directly on the assembly surface.

Roboschalt

DAKoTA

Moonshiner

Learn more about Schubs and how we've been leading switch control experts since the 90s.

Learn more about Schubs and how we've been leading switch control experts since the 90s. Learn how our responsible engineering & sustainable practices create long-term value for our customers and our planet.

Learn how our responsible engineering & sustainable practices create long-term value for our customers and our planet. UL-certified for peace of mind. We build control cabinets that are a mark of quality, precision, and global safety standards.

UL-certified for peace of mind. We build control cabinets that are a mark of quality, precision, and global safety standards. Take a look at some of the services offered by Schubs and see how we can help you!

Take a look at some of the services offered by Schubs and see how we can help you! Follow our process from planning to the finished product.

Follow our process from planning to the finished product. Learn how Schubs continuously adapts to digitalisation for our manufacturing.

Learn how Schubs continuously adapts to digitalisation for our manufacturing.